Sale!

Original price was: $179.99.$97.99Current price is: $97.99.

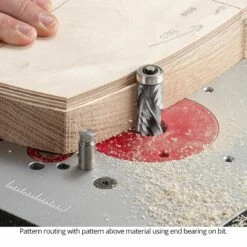

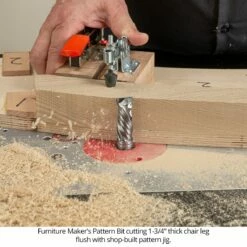

Ultra-Shear’s 3/4″ Compression Pattern and Flush Trim Bit makes your pattern-routing projects go smoother and safer. With a bearing both above and below the cutting area, you can cut with the pattern on either the top or bottom of your material. Add to that the mass of the 3/4″ cutting diameter and the double-shearing action of the compression edge geometry and you have a bit that speeds up your routing, minimizes sanding and avoids grain tear-out.

- Shop with ease, buy with confidence.

- 100% Quality Satisfaction

- Free Shipping, No Compromise on Quality

- Your needs, our top priority.

Reviews

There are no reviews yet.